Statues and honors

Comments are logo here

IBCCO, as one of subsidiaries of Middle East industries development holding company (MIDHCO), Has initiated its activities on copper industries from 2010

More infoIranian Babak Copper Company, proudly, uses the latest technology in the world in the production of copper pipe by cast & draw method (the fourth line launched in the world) and the most advanced cathode production technology in the world by bioleaching method (the first line launched in this way in the world) for its productions to take a big step towards the independence and prosperity of our dear country "Islamic Republic of Iran".

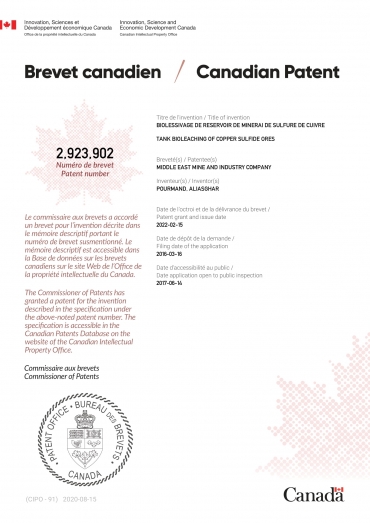

The largest copper production unit in the world by Bioleaching Tank method is under construction in Iran by Babak Iranian Copper Company, with a nominal annual production capacity of 50,000 tons of cathodic copper, in 23th km north of Shahr-E-Babak city in Kerman province. Lab studies, pilot and process design of the unit have been done by EPCM, a Canadian company, and the executive operations of the project started on 17th Aug, 2011 and in 2018 the first phase (30% of the capacity) was launched. In this method, copper cathode is produced by using thermophile microorganisms in acidic solution and by dissolving sulfide copper concentrate. Then, using the conventional method of solvent extraction and electrowinning, copper with A LME grade (99.995%) is produced.

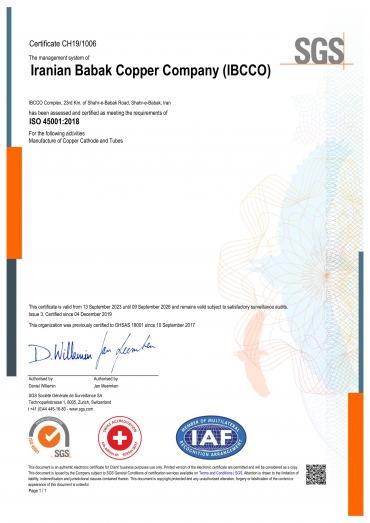

In the way of Improving the quality of manufactured products along with reducing production costs, avoiding pollution in the production process and also diminishing the cost of the products, Iranian Babak Copper Company has decided to use the latest and most unique production methods to produce all kinds of copper pipes and copper cathode with the highest quality and in accord with world standards.

In order to maintain, upgrade and continuously improve the quality of products, the quality control and laboratories department of Iranian Babak Company, operates as an independent unit in two cathode and copper pipe factories of the company and with accurate and modern laboratory equipment, by performing the required tests by qualified and trained personnel, produces high-quality products in accordance with ASTM, EN and JIS standards. The scope of the activities of the quality control unit is necessarily and essentially in line with the production units, from the initial stage i.e., the purchase of raw materials to the final stage i.e., providing the product to the customers.

Comments are logo here